-

Polished Stainless Steel Corner Protectors (127)

-

Stainless Round Bar (34)

-

Stainless Round Bar - Grade 303 (17)

-

Stainless Round Bar - Grade 304 (17)

-

Stainless Square Bar (6)

-

Stainless Steel Flat Bar (40)

-

Stainless Steel Folded Angles (127)

-

Stainless Steel Round Tubes (11)

-

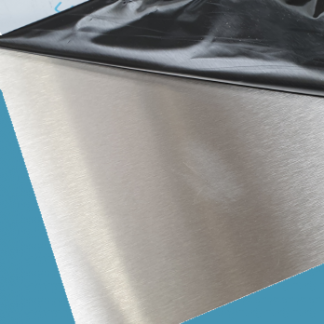

Stainless Steel Sheet - 2B Finish (9)

-

Stainless Steel Sheet - Bright Finish (10)

-

Stainless Steel Sheet - Brush Polished (Kitchen Splashbacks) (13)

-

Wall Fixing Kits (3)

1st Choice Metal are your first place to go to when looking for Stainless Steel metals. Stainless Steel is the name for Carbon Steel that has a minimum of 10.5% Chromium added to its composition. This 10.5% figure varies dependant on the actual grade of Stainless Steel, but 10.5% is the minimum amount of Chromium required in order for the alloy to be termed as Stainless Steel. As well as the Chromium, Stainless Steel is made from mainly Iron (around 60%) and varying smaller amounts of other metals such as Nickel, Titanium, and Copper complete the composition of the alloy.

The main benefit of Stainless Steel is its resistance to corrosion, and this is all down to the addition of the Chromium. When the Chromium meets oxygen, it mixes to form a microscopically thin layer of oxide over the surface of the material. Imagine dividing a millimetre into 750 equal parts – one of those is approximately the same thickness as this layer of oxide! Despite being so thin, it is this layer that protects the metal below from corroding / rusting. As a general rule of thumb, the higher the percentage of Chromium in the material, the more corrosion resistant it will be.

As well as being able to withstand the elements, Stainless Steel is also a very hard and also a very strong metal. In recent times this has seen it being used more and more in the construction industry as it’s durability and corrosion resistance are benefits that outweigh its comparable high cost versus carbon steels. You will also commonly see Stainless Steel used in and around buildings for radiators, light fittings, lifts, cladding, signs, railings & balustrades on steps & stairwells, and sanitary ware in toilets – items such as toilets, gent’s urinals, sinks, units, taps, bins, toilet roll holders & towel rails are all often fabricated from Stainless Steel.

As a generalisation, Stainless Steel is also very good at resisting acids. Although of course there are many different types of acid and many different grades of Stainless Steel and therefore some grades of Stainless are more suited for use with certain types of acid than others.

One of the most bizarre things about Stainless Steel is that it is not actually stain proof! Whilst it is very stain resistant it can tarnish over time due to several factors; the main ones being type / grade of stainless and the environment it is used in. Stainless Steel is very easy to keep clean, and usually warm soapy water is sufficient, however for tougher marks / stains there are plenty of specialist cleaning products available.

Both grades 304 & 316 are FDA certified as food safe and for this reason the food and beverage industries are massive users of Stainless Steel. Just about anything that comes into contact with food can be found manufactured from Stainless Steel – the containers that you see on the road transporting liquids such as milk and beer, to the machines in factories that process & package our food; the worktops, splashbacks, utensils, ovens & fridges used in restaurants to prepare our food, the cutlery that we use to eat our food, and even the inside of the dishwasher that we use to clean our plates and cutlery afterwards – they are all made from Stainless Steel!

The automotive industry is another area where Stainless Steel is very common. Intake & exhaust valves, catalytic converters, silencers and exhausts, clamps, clips & brackets are all often manufactured from stainless steel on cars & motorcycles due to its corrosion resistance. Car & motor bike enthusiasts will often modify their vehicles by manufacturing their own replacement parts and trims out of Stainless Steel as not only is it weather resistant, it is also great for polishing; and mirror polished components really enhance the look of any engine bay.

We currently stock a range of Stainless Steel Round Bars in both Grade 303 which is the free machining grade & also grade 304 which has decent machinability & excellent weldability.

We have the following diameters are on the shelf, ready for immediate despatch….

- 3mm dia

- 3/16” (4.76mm) dia

- 6mm dia.

- 8mm dia.

- 10mm dia.

- 12mm dia.

- 16mm dia.

- 20mm dia.

- 25mm dia.

- 30mm dia.

- 35mm dia.

- 40mm dia.

- 50mm dia.

- 2.1/4” (57mm) dia.

- 2.1/2” (63.5mm) dia.

- 70mm dia.

- 3” (76mm) dia.

Stainless Steel Flat Bars & Stainless Steel Square Bars are all stocked in grade 304 in a large combination of widths, thicknesses & lengths. From smaller sizes such as 20mm x 3mm Flat Bar & 12mm x 12mm Square Bar stock, through to heavier profiles like 100mm x 12mm Flat and 25mm x 25mm Square – you can order them cut to size and delivered quickly right here.

We have top quality grade 304 sheet on the shelf in a choice of thicknesses and finishes, ready to be sheared to the buyers required sizes and despatched immediately.

Bright Annealed Sheet – similar to a bright or mirror polish – in the following thicknesses: 0.9mm, 1.2mm & 1.5mm.

Dull Polished Grade 304 Sheet (Dull polish aka Brush Polish) in 0.9mm, 1.2mm, 1.5mm & 2mm Thick.

2B Finished Grade 304 Sheet in 2mm & 3mm thick.

Should you require any diameters, sizes, thickness, lengths or grades (such as 316 or 430) that we don’t currently stock, then please don’t hesitate to contact us for a competitive quote – most non stock items are still available for despatch in 24 – 48 hours – so go on, give us a try!